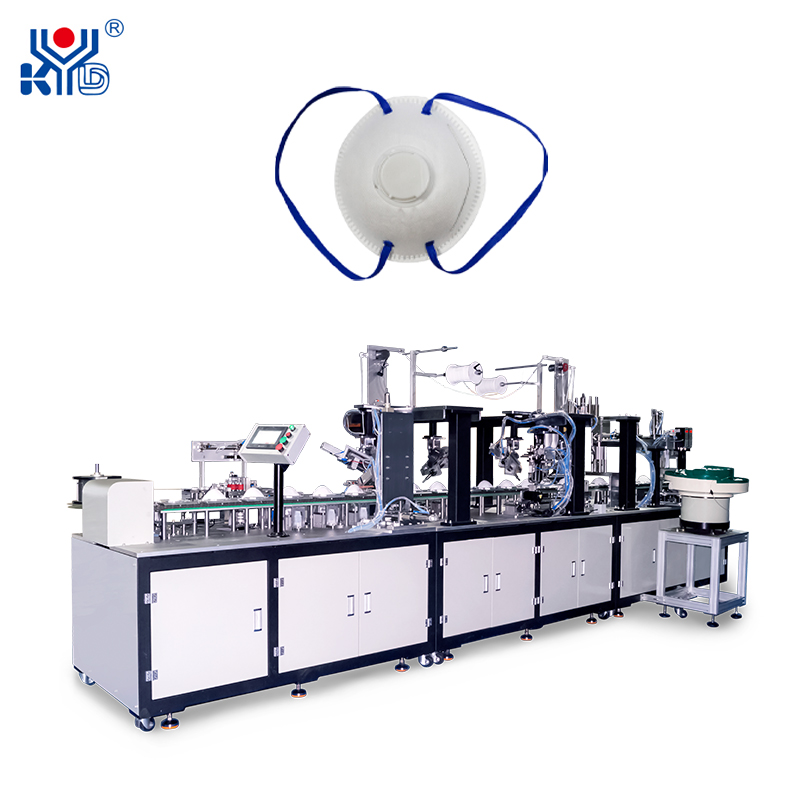

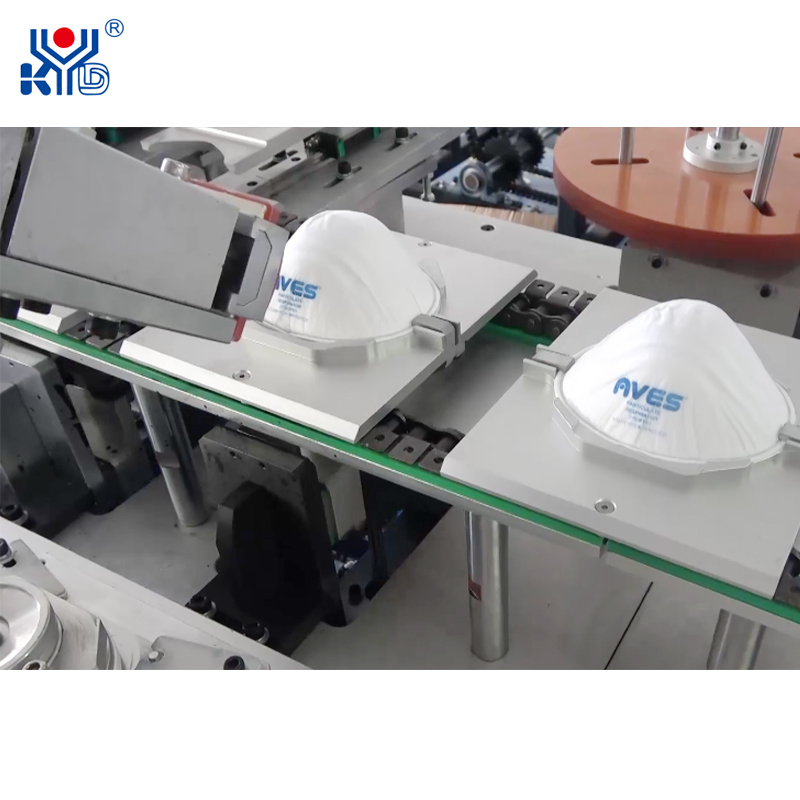

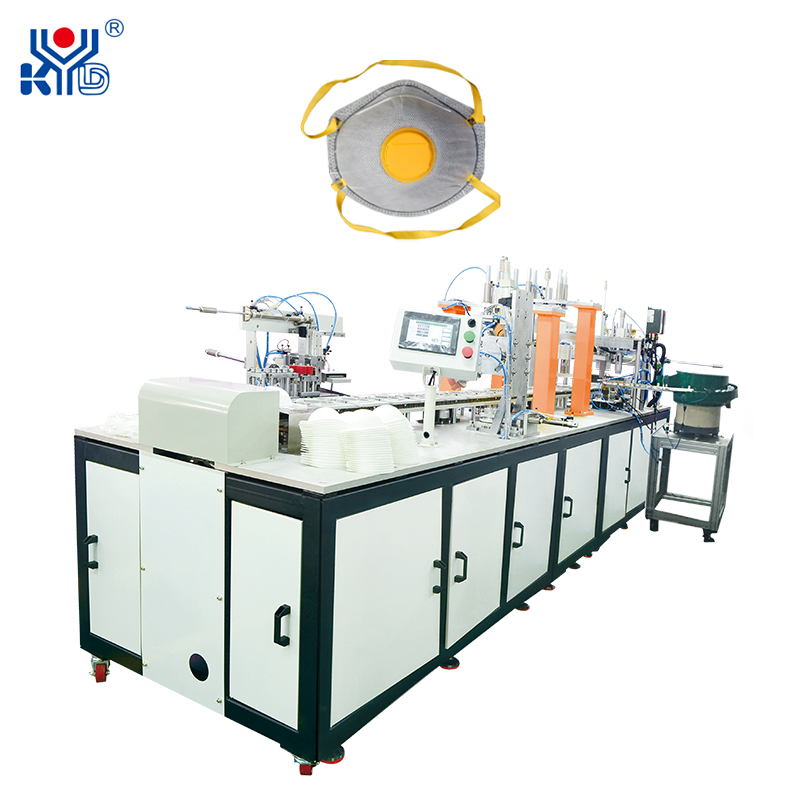

Automatic Cup Mask After Process Making Machine(oblique welding ear-loop)

- Date:2023-11-07

- Visits:1090

- Product introduction

- Related products

Environmental conditions

1) Temperature: the normal ambient temperature shall be between 5°C and 40°C.

2) Humidity: 30% ~ 90%.

3) Keep away from paint (gasoline), chemicals, acid, alkali and explosives or inflammables.

4) Avoid proximity to machines that produce vibrations.

5) Ambient lighting: above 300LUX.

3. 3. Installation Precautions

1) After positioning the machine, adjust the foot cup of the machine and use the horizontal auxiliary tool until it is adjusted to the level.

2) Connect power cables. The machine uses 220V single-phase, 50HZ power, strictly prohibited to connect 380V or other power does not meet the requirements, please pay special attention to the user! To ensure safety, the connection work must be completed by electrical professionals, with connection wire. If it is equipped with a power plug, 2.5m㎡ three-core cable must be used to correctly connect live line (L), neutral line (N) and ground line (E).

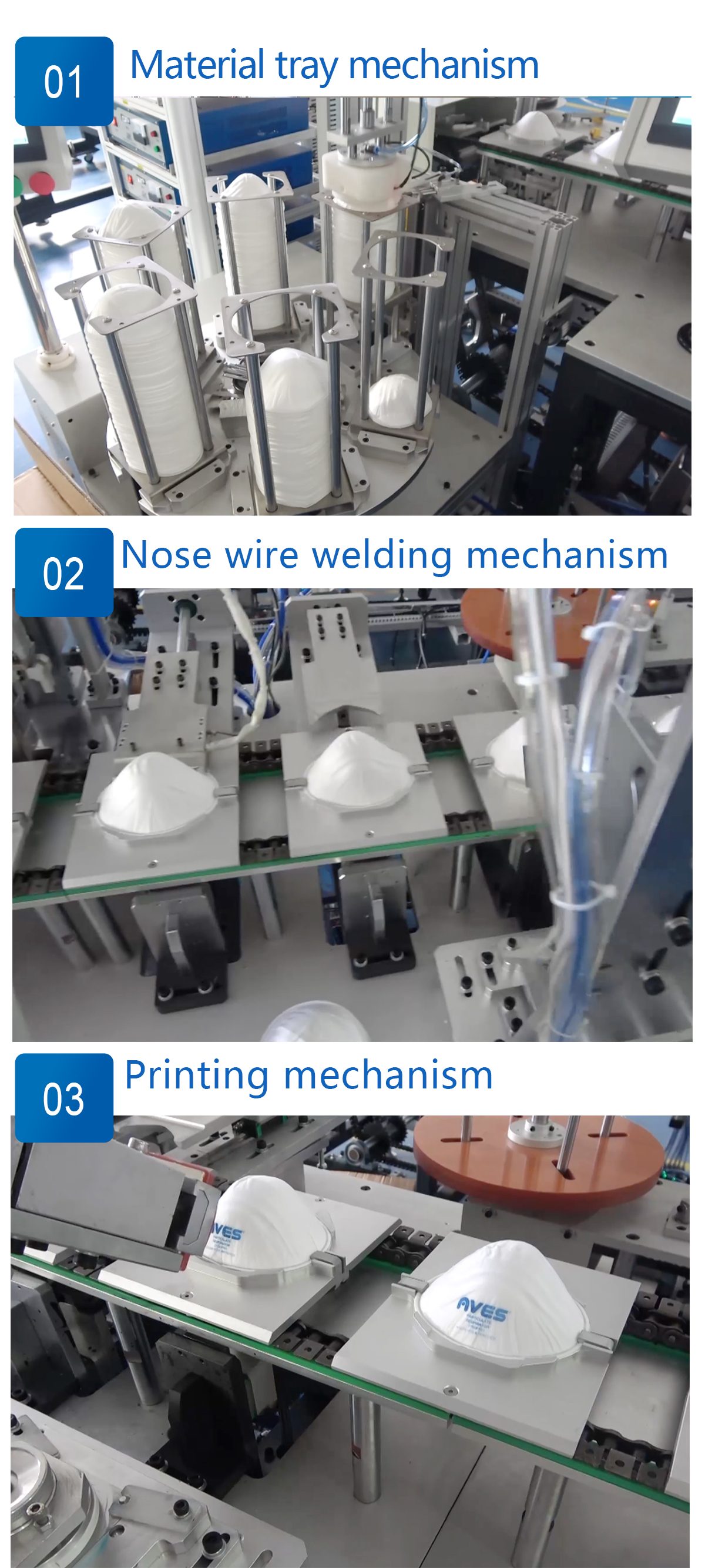

Four, the working principle of machinery

4.1 Ultrasonic welding mechanism

1) Structure diagram

1. Ultrasonic steel film: flat die, weld mask shape together with welding wheel.

2, ultrasonic fixed block: fixed support ultrasonic steel film

3. Ultrasonic transducer: it is the energy that the welding wheel can fuse out the shape of the mask.

4. Fan: Dissipates heat.

2) Working principle:

Through the tension of the guide roller, the ultrasonic steel film interacts with the welding wheel to weld the cloth, and then passes through the drawing mechanism. Under the action of ultrasonic waves, the cloth is fused together and then moved to the next process.

Product Name

Automatic Cup Mask After Process Making Machine(oblique welding ear-loop)

Detection mode

Photoelectric detection

SIze

5720*1850*2120mm

Voltage

220V

Power

6KW

Pressure

6kg/cm2

Yield

20-25pcs/min

Control Mode

PLC

-

Cup Mask Nose-wire Heat-sealing Machine with Pad Printing

Cup Mask Cover Making Machine

Automatic Cup Mask After Process Making Machine (horizontal welding earloop)

Cup Mask Welding And Cutting Machine

Cup mask forming machine

Cup Mask Breather Holes Punching Machine

Automatic Cup Mask After Process Making Machine(horizontal welding ear-loop)

English

English